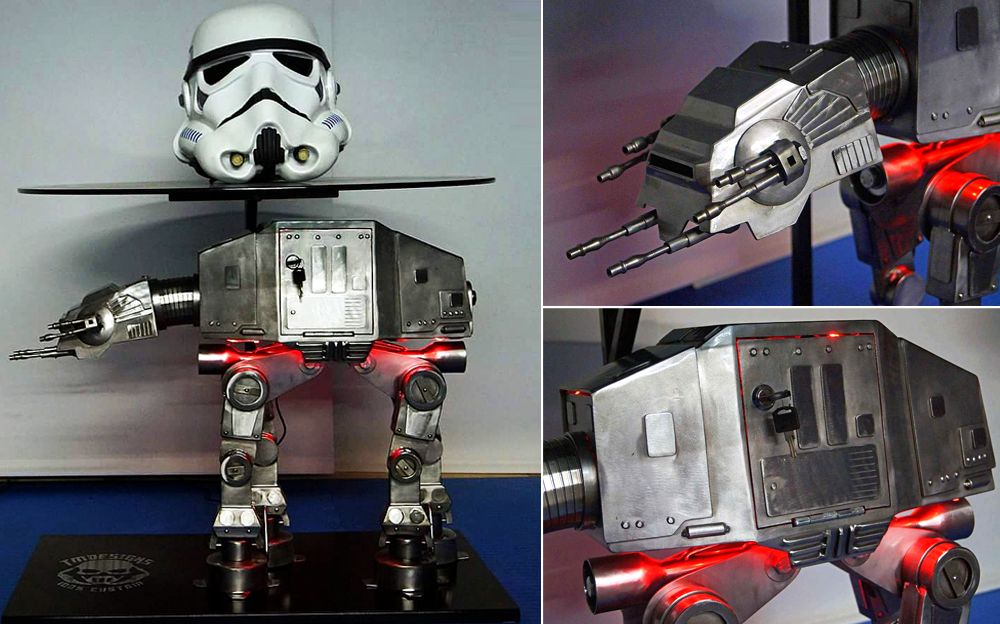

Rarely do you come across a custom furniture design which instantly appeals with its oomph factor! Folks, this is the ATAT Walker Table designed by the talented David Taylor of TMDesigns, which will surely be an object of desire for diehard Star Wars fans. Bearing every small detail of the all-terrain fighter used by the Imperial Army, this coffee table (if we can call it so) is tailor-made for a Star Wars interior.

Being a steel fabricator for indoor and outdoor settings, David takes pride in what he does. And that is evident from the ATAT Walker Table which David says is one of his best builds so far.

Crafting the table was not easy as it took almost 280 individual steel pieces to take shape. Using six spray cans and countless sanding disks, the ATAT Walker finally came to life. It’s not surprising that with almost 105 man-hours invested in the build, this looks perfect for a man cave.

The custom-made table comes at a steep price tag of £1,299 (~$1,700), which is completely justified considering the amount of skill and effort put into the making. Perhaps, a fat-pocketed Star Wars fan would be eying it already!

We got in touch with David and he was generous enough to answer our inquisitive queries regarding his work and life. So here is how the conversation went with the creative DIYer.

HomeCrux: Tell our readers something about yourself?

David Taylor: My name is David Taylor, from the greater Manchester area in the UK. I’m 35 years old, married and a father of 2.

I started off by working in warehouses and then helped my dad with his garden rounds, after a few years I then bought half the gardening business from my dad and started running it on my own.

My love of building/creating started at the early age of 5 when I stripped and rebuilt my BMX. I have always loved to build, fix and recreate lots of different things. Over the years I have put my hands to good use and tried rebuilding minis, tinting car windows or fixing almost any broken tools people brought me.

I think one of my favorite rebuilds at that time was a broken red bike. I completely stripped it back to basics, cleaned it all out got the engine running and then gave it a special custom spray paint all done in my little man shed!

My dad… Stuart Taylor is a big influence on me. He was a staff sergeant in the army and one of his many roles included repairing tanks, guns and also crafting custom parts for machines. These were my first memories of me helping and getting my hands dirty.

I believe this was the foundation and start of my self-taught fabrication career.

HomeCrux: How did your journey with TMDesigns start?

David Taylor: TMDesigns started as just a hobby with me tinkering in my man shed, from building my first steel sculpture ‘Johnny 5’ to my most recent epic build the ATAT Walker.

Things have certainly changed since the early hobby/tinkering stages, I now have many of my designs all over the world in countries including America, Poland, Canada, France, and Germany.

These include designs such as wall art, steel business logos, tattoo armrest and football signs for super fans.

I have also been asked to do a few memorial pieces for families who have lost loved ones through illness or family members who have lost soldiers.

What started as a hobby is now a big dream of mine to continue to build epic designs with most of them being one of a kind pieces.

Big dreams can start in small spaces… from my small man shed of 10” x 8” to my recently built new workshop of 27” x 12”.

Not bad for someone self-taught. I really believe you can’t teach these skills in college. You either have it or don’t… Luckily I do and still, love going into my workshop every day like it was my first.

I’m happy to take on any request and will put in 100% of myself into each of my builds, whatever the size or meaning of the piece … my wife always says, of course, you can make that … which I laugh at her, but I know she’s right !!!

HomeCrux: How did ATAT Walker Table come to life?

David Taylor: My latest build the ATAT Walker table recently completed. It consists of 280 individual steel pieces all cut out by hand, welded and shaped by hand, this has been one of my biggest builds and most dangerous … as my hands have taken a beating on this one!!!!

The next process on the ATAT was to fabricate and paint the custom table stand. This is spray painted by hand firstly with primer, then 2 color coats and finally the 2 top coats of clear lacquer.

When all the fabrication work was done on the ATAT it was then stripped back down into 3 sections … body, axle, and legs all cleaned thoroughly before 3 coats of clear lacquer was applied. Once fully dry, I reassembled it into the final product with only a few finishing touches i.e. remote control LED lights and inner felt.

HomeCrux: Where do you find inspiration for your projects?

David Taylor: My inspiration starts with each and every one of my customers, they each have an idea of what they require. They begin by giving me a vague description of what they would like me to build and from there the rest is in my head.

I do put a lot of research into each and every one of my builds by looking at many various images from different angles/views to help me along the build. I can spend hours, days or even weeks thinking and researching how the build will go.

I try my best to write/text the customer with how I see the build will go but as I don’t design on paper as I’m not the best drawer they really do put their faith in me … and so far all my customers have trusted me and what is in my head as an artist for their designs.

Luckily so far this process hasn’t failed me yet as I haven’t had any bad reviews or unhappy customers.

HomeCrux: Can you brief our readers about the build process?

David Taylor: The build process for most of my builds starts the same way… plenty of research and then the visions in my head and then transferring that best I can to paper templates before cutting it out of steel, welding it together, grinding, painting and lacquering.

The next process is the grinding of the welds on the steel to a seamless finish … many people have said I’m a little OCD when it comes to my clean finishes!!! For me this is one of the most important stages, this is where I guess my hard work is hidden I really want all my pieces to be seamless and clean.

I hate rough edges as I believe it makes it look unfinished. I enjoy the feedback I get from my customers when they see the design up close and ask how and where did you start!

HomeCrux: Some of your favorite builds so far?

David Taylor: Starting from ATAT Walker Table, Jaws Table, Batman Minion Table, Captain America Minion Table, 300 Sculpture, Mark 1 Escort Table, French maid Minion Table to the Lego Homer Simpson Minibar, Lego Woody (Toy Story) Minibar, Gold Lego Bender (Futurama) Table, LifeSize Bender (Futurama) BBQ, Terminator Sculpture and Predator Sculpture.

Thor Hammer is my wife’s choice, so it is worth mentioning here. Other than that Darth Vader Table and my very popular Beauty and the Beast forever roses are among my favorites.

Follow Homecrux on Google News!